Our Facilities List

Our Swiss-style machining experience gives us the capability to make complex geometric parts. We have extensive capabilities and experience in precision aerospace CNC machining and many axes of our Citizen Swiss lathes.

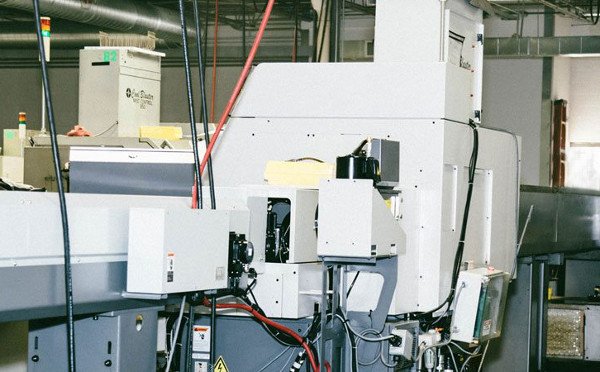

Precision Swiss-style CNC Machining Facilities

(1) Citizen Cincom L3-20 VII – Multi-axis Swiss lathe w/ Sub spindle capability – 0.812” maximum bar diameter – live cross work positions

(1) Citizen Cincom L5-20 VII – Multi-axis Swiss lathe with Sub spindle capability – 0.812” maximum bar diameter –live face and cross work position – C axis milling capability – High pressure coolant

(3) Citizen Cincom L20 IX – Multi-axis Swiss lathe with Sub spindle capability – 0.812” maximum bar diameter – live face, end and cross work positions – C axis milling capability – High pressure coolant

(1) Citizen Cincom L20 X – Multi-axis Swiss lathe with Sub spindle capability – 0.812” maximum bar diameter – live face, end and cross work positions – C axis milling capability – High pressure coolant

(2) Citizen Cincom M1-20 – Multi-axis Swiss lathe with Sub spindle capability – 0.812” maximum bar diameter – 20 live face and cross work positions – C axis milling capability – High pressure coolant

(2) Citizen Cincom C32 – Multi-axis Swiss lathe with Sub spindle capability – 1.250” maximum bar diameter – live face and cross work tooling – C axis milling capability – High pressure coolant

(1) Citizen Cincom L32 VIII – Multi-axis Swiss lathe with Sub spindle capability – 1.250” maximum bar diameter – live face and cross work tooling – C axis milling capability – High pressure coolant

(1) Nexturn SA32D – Multi-axis Swiss lathe with Sub spindle capability – 1.250” maximum bar diameter – live face and cross work tooling – C axis milling capability – High pressure coolant

(1) Nexturn SA38E – Multi-axis Swiss lathe with Sub spindle capability – 1.50” maximum bar diameter – live face and cross work tooling – C axis milling capability – High pressure coolant

(2) Citizen Cincom L12 – Multi-axis Swiss lathe with Sub spindle capability – 0.500” maximum bar diameter –live face, end and cross work positions – C axis milling capability – High pressure coolant

Additional Facilities Value Adds:

- Full Quality Lab (certified according to ISO 9001:2015) with Mitutoyo Vision system

- Branson Vapor Degreaser/Ultrasonic cleaning Grit/Glass/Sand blasting

- Vibratory finishing/de-burring Surface grinder

- Grit/Glass/Sand blasting

- Surface grinder

- Bridgeport manual milling machine

- Hardinge hand lathes

- Drill presses

- Inventory maintained tooling crib

How Can We Help?

For general inquiries or assistance, please fill out the easy form below. If you are looking for a Quote for a particular project, please use our RFQ page to ensure your request is received by the correct department.